-

Clean booth/Purification booth

Purification shed, clean shed, dust-free shed, dust-free work shed, clean shed is a simple purification device with low investment, high purification level, and easy mobility. Place the clean laminar flow hood FFU on a frame assembled from professional purified aluminum profiles. The top is covered with blind plates, with tight seams, surrounded by anti-static curtains/anti-static organic glass seams, and the bottom of the perimeter is ventilated using positive pressure natural ventilation to achieve a cleanliness level of 10-10000 in the shed area. It has the characteristics of fast installation, short construction period, low price, and easy mobility. Controlling the main production processes in a smaller environment is also the best choice for clean room design.

more>>

-

Clean bench/dust-free workbench

The advantages of the ultra clean table are easy and comfortable operation, high work efficiency, short preparation time, and can be operated in more than 10 minutes after turning on, which can be used at any time. In factory production, when the workload of inoculation is large and requires frequent and long-term work, a super clean table is an ideal equipment. The ultra clean bench is powered by a three-phase motor with a power of about 145~260W. The air is blown out through a "super filter" composed of specially made microporous foam plastic sheets laminated together to form a continuous, dust-free and sterile laminar flow of ultra clean air, the so-called "efficient special air", which removes dust, fungi, bacterial spores, etc. larger than 0.3 μ m. The flow rate of ultra clean air is 24-30m/min, which is sufficient to prevent pollution caused by possible air disturbance nearby. Such a flow rate will not hinder the use of alcohol lamps or Bunsen lamps for burning and disinfecting equipment. The staff operates under such sterile conditions to ensure that the sterile materials are not contaminated during the transfer and inoculation process. But if there is a power outage during

more>>

-

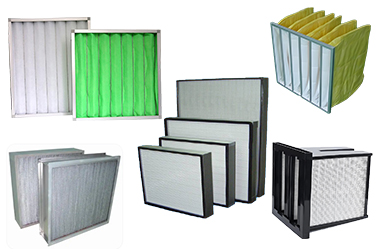

Cleanroom consumables/junior high-efficiency filters

High efficiency air filters can be widely used in the air conditioning end supply of dust-free purification workshops in industries such as optical electronics, LCD manufacturing, biomedicine, precision instruments, beverages and food, PCB printing, etc. Efficient filter efficiency: 99.99% @ 0.3um. Both high-efficiency and ultra high efficiency filters are used at the end of the clean room, and can be divided into: high-efficiency with partitions, high-efficiency without partitions, high-efficiency with high air volume, and ultra high efficiency filters based on their structural forms

more>>

-

GMP Medical Devices/Pharmaceuticals

The decoration requirements for sterile medical device purification workshops mainly include the following aspects:

1. Cleanroom level:

-According to the requirements of the Good Manufacturing Practice (GMP) for Medical Devices, the production of Class II non sterile medical devices typically requires compliance with ISO 7 cleanroom standards.

2. Air purification system:

-Install primary, medium, and high-efficiency filters (HEPA) to effectively filter out particulate matter in the air.

more>>

-

Purification for electronics/food/cosmetics

In the process of food production, clean decoration is an important link to ensure food safety.

Unlike ordinary factories, food factories have strict requirements for cleanliness, pollution prevention, and hygiene management.

more>>

-

PCR laboratory/operating room purification

Surgery has strict requirements for site selection and layout in hospitals. It is usually located in the core area of the hospital, away from areas with high foot traffic, to reduce the entry of bacteria and dust.

The operating room group generally includes the main operating room, sterile preparation area, anesthesia preparation area, postoperative recovery area, etc. These areas are closely connected and the flow design is reasonable to reduce the pollution risk caused by personnel movement.

more>>